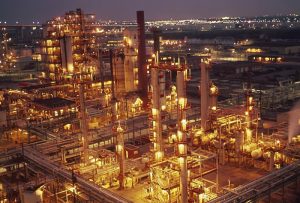

As the production base for crude oil cracking, chemical plants are mostly explosion-proof areas in Zone 1 and Zone 2. From heavy

oil separation to light oil undergoing catalytic cracking process, it is necessary to press and press into various organic branch components to participate in the reaction. In the production process, the explosion-proof motor is used to drive the pressure pump, and various ingredients participating in the reaction are added.

At a certain temperature, crude oil will be cracked into various light-density oils and organic gas-like substances. These factories are to work without interruption for 24 hours. so explosion-proof lights are a necessary condition for lighting in production workshops and pressure vessels.

In addition, the outdoor area of chemical plants requires good waterproof and corrosion resistance. At the same time, most of them are a few meters or hundreds of meters in high altitude areas, high temperature and high pressure, the lamp sreplacement and maintenance are extremely difficult. Therefore, the use of lamps in chemical plants is not just for lighting, but more emphasis on safety and reliability.

CESP’s explosion-proof led lights designed for chemical plants are strictly compliant with UL, CUL, DLC, IECEX, ATEX, and EX standards in terms of technology and lighting, and the protection class is IP68 to meet our customers requirement.